Lithium Ion Batteries

Emergency Lighting evolves with technology and LED is now the main light source used for safety, performance and reliability. What has lagged behind is the battery technology, that is until now.

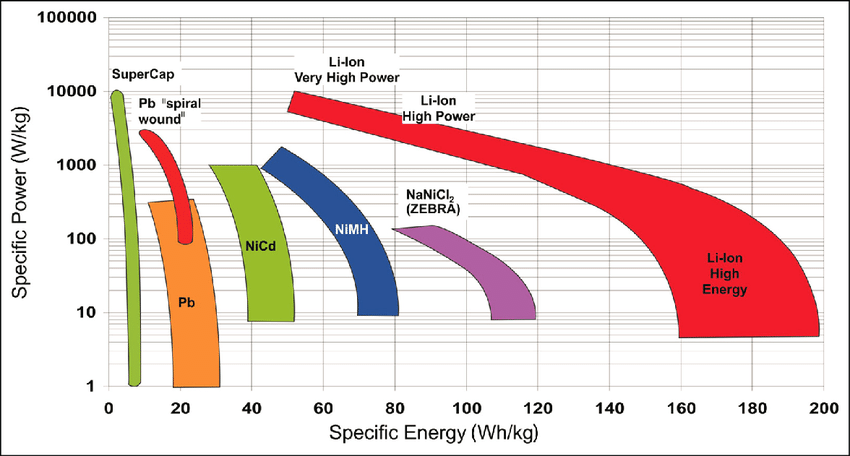

Previously, emergency luminaires (which is always the last consideration in a new build or refurbishment anyway) operated on mains voltage Halogen, Fluorescent or occasionally Compact Fluorescent lamps. These light sources could cope with NiCad (Nickel Cadmium) batteries which invariably have a lower energy density, they tend to self-discharge and so meaning you need to check and re-energise them before use. This can be a drain and take a long time when on site, but they are cost effective and were used for a long time in the industry mainly due to their good temperature operating range

Then along came NiMH (Nickel Metal Hydride) which typically had a 30 to 40% higher capacity than NiCad, and a potential higher density.

They were also less susceptible to memory charging effects and were better with lower temperature requirements for storage and transport.

Not much changed in the industry but the appreciation of emergency circuits along with self-testing, monitoring did start to gain interest and attraction for clients.

The Internet of Things (IoT) has been lauded for some five years or more now and has not really taken off yet but it has drawn attention to integrated systems protection for buildings and joined up monitoring. This very welcome boost has been terrific for emergency lighting and prompted a few manufacturers to seek the next generation of system (battery and fitting designed in tandem).

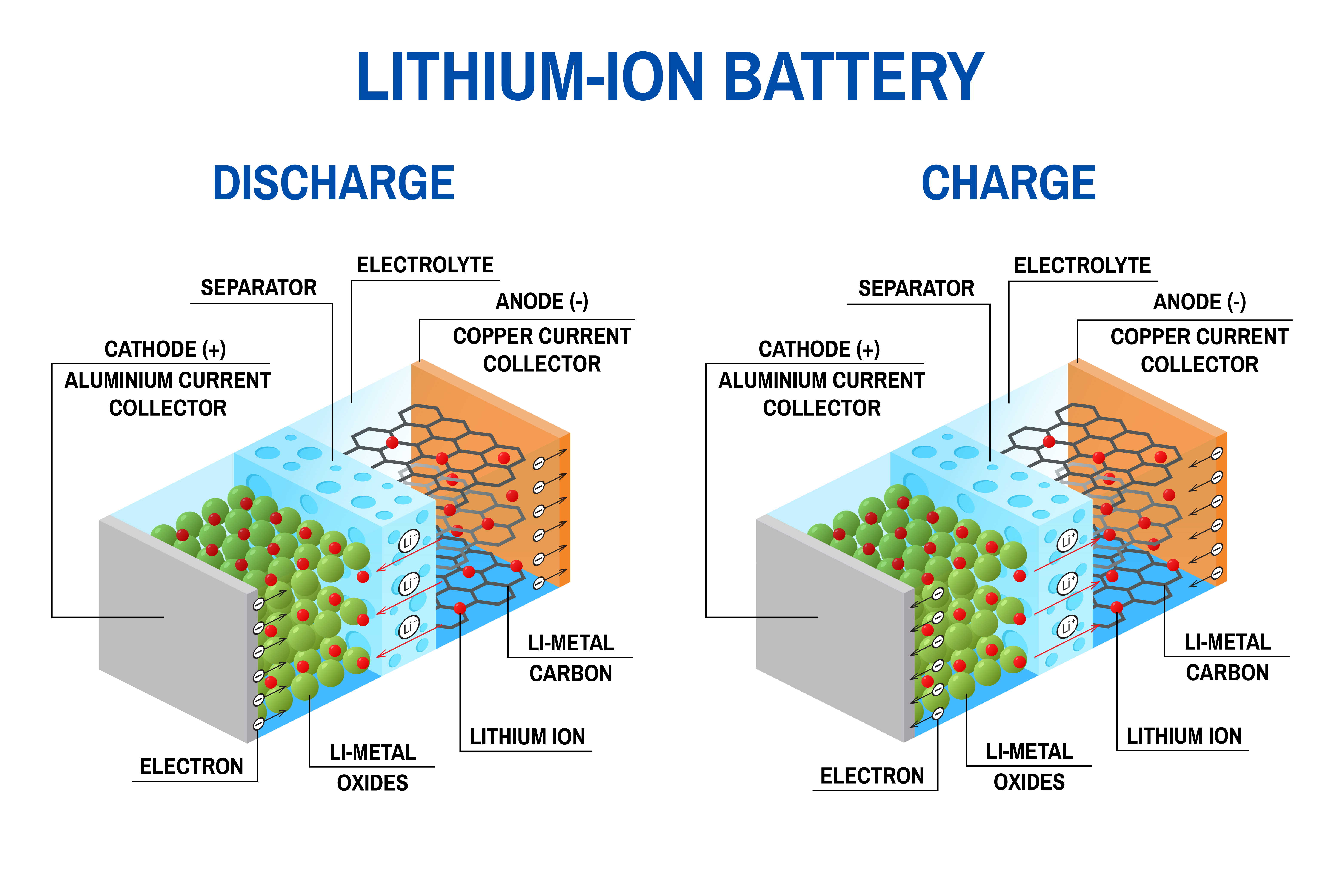

Lithium Ion batteries (Li-ion) are now the new standard offering terrific versatility, they really are the best designed battery cells for demanding emergency lighting performance.

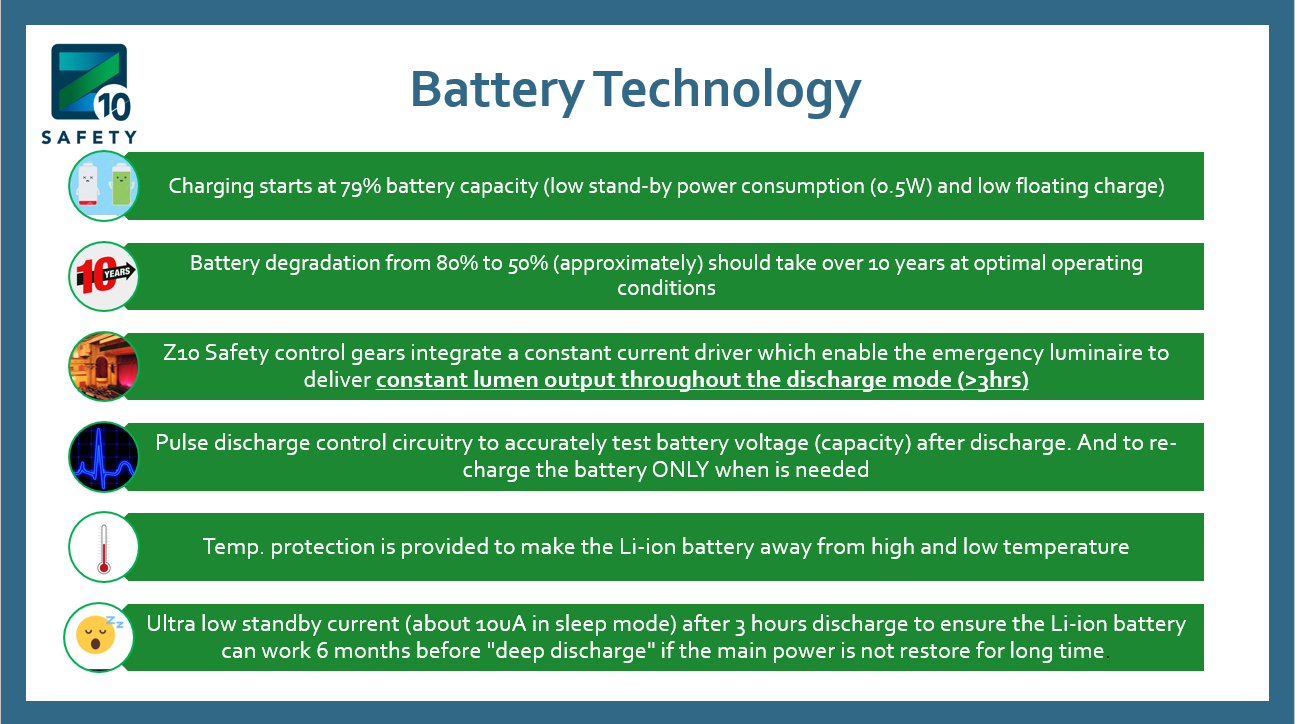

Boasting an array of features:

- Environmentally friendly (Lithium is not a hazardous waste).

- Lightweight & Compact

- High energy density packs a bigger punch.

- Low maintenance, can be charged at any time.

- Operates at higher temperatures.

- More discharge cycles so longer lasting useful life.

- Low self-discharge rate (3/5% monthly)

- Shorter charging times reduces time/cost on site to do testing.

They do need a charge and can become damaged if stored for a long time with no charge and at the moment they are more expensive to buy than NiCad but in terms of value for money over the life they are well worth the investment.

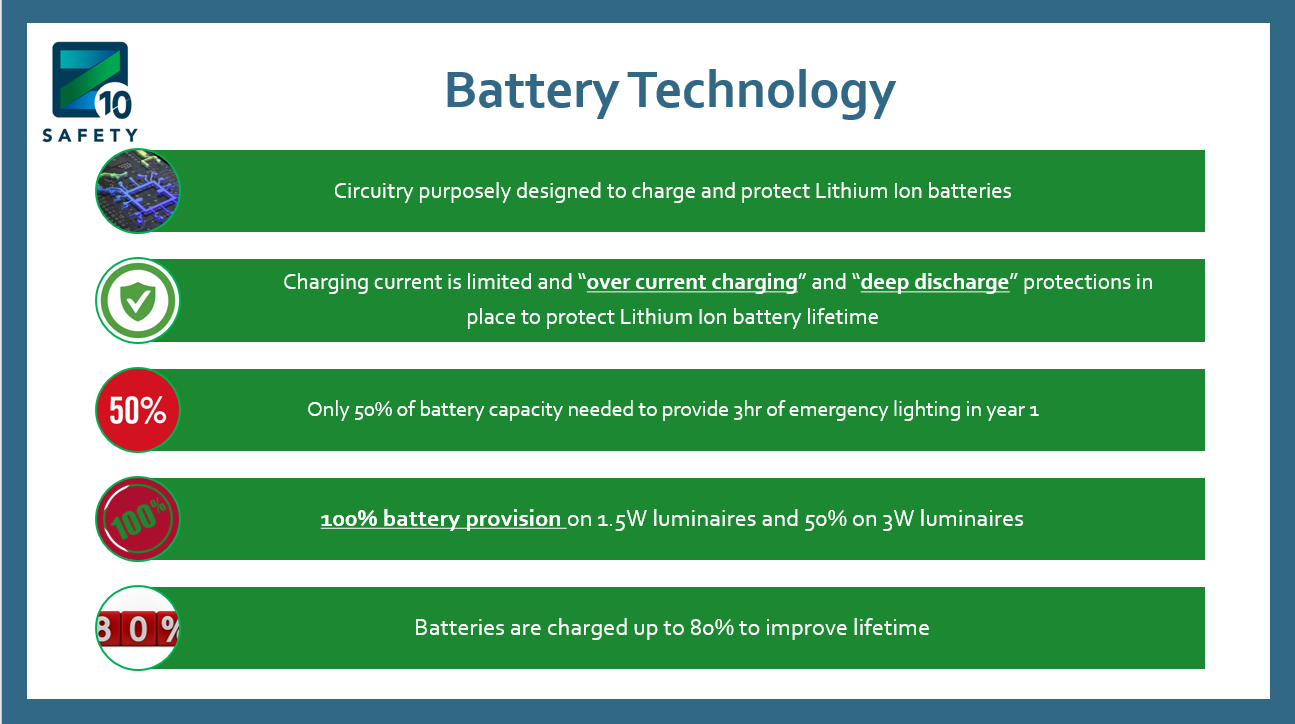

Charging current is limited and “over current charging” and “deep discharge” protection is in place to protect Lithium Ion battery lifetime.

Energy Saving batteries?

Yes, they are! The batteries are only charged up to 80% to improve lifetime when new. During use they don’t trickle charge like other types so the standby power (and cost) is zero. Re-Charging starts at 79% battery capacity (low stand-by power consumption (0.5W) and low floating charge. So in effect the battery charges itself from 79 to 80%, that 1% doesn’t take long at all and costs even less than you might think. This technique alone can save £27.80 a year per luminaire because of the charging regime. Z10 PCB’s and batteries were designed together to complement performance.

Z10 Safety control gear integrates a high quality constant current driver which enables the emergency luminaire to deliver constant lumen output throughout the discharge mode (>3hrs).

In addition, we use pulse discharge control circuitry to accurately test battery voltage (capacity) after discharge and to re-charge the battery. The key benefit of Li-ion is that by measuring the voltage we can tell exactly how full the battery is, something NiCad cannot do.

There’s more. An Ultra-low standby current is used (about 10uA in sleep mode) so that after 3 hours of discharge to ensure the Li-ion battery can work 6 months before a “deep discharge” if the main power is not restore for long time.

When you design a PCB and battery together you get more better performance and reliability, that is one of the reasons Z10 Safety is comfortable to guarantee our system (including the batteries) for five years. We undertake extensive testing in our factory and operate the batteries 24/7 at three different temperatures ranges so ensure performance, which the data shows us is truly exceptional.

Our goal is to help customers and building managers have the versatility of choice. Ideally every building will contain its own eco system of self test luminaires to keep themselves ready for the first time they are needed (but hopefully never will be). As the old adage goes “it’s better to be safe than sorry”, we prefer “it’s better to be Z10 safety than sorry”.

Related Information

MT (Manual Test)

MT emergency luminaires must be tested by accredited engineer. Optional ARC remote control adds extra functions. Learn More

AST (Advanced Self-Test)

AST emergency luminaires are self-test units. ARC remote control gives the possibility to add extra functions with ARC remote control. Learn More

PST (Programmable Self-Test)

PST emergency luminaires can be programmed with PRC remote control to meet specific end-user requirements. Learn More